We are shaping the future of industry by supporting our customers to digitize their industrial machinery: Hydropa 4.0 stands for connecting processes and machines by using state-of-the-art information-and-communication technology.

The new Hydropa SmartTechnology is customized for monitoring, maintenance and repair of industrial machinery: The easy-to-handle software keeps track of the current status of power packs and machines. Notifications inform about critical developments, enabling our clients to take action by initializing preventive maintenance - this will reduce production losses caused by unscheduled standstills to a minimum.

The innovative Hydropa SmartTechnology helps our clients to reduce operating and maintenance costs - by up to 30 percent!

The progressive digitization of machines and processes is very convenient: Many cars for example monitor data on wear-and-tear parts like brakes as well as fluids and remind the driver of the next service appointment.

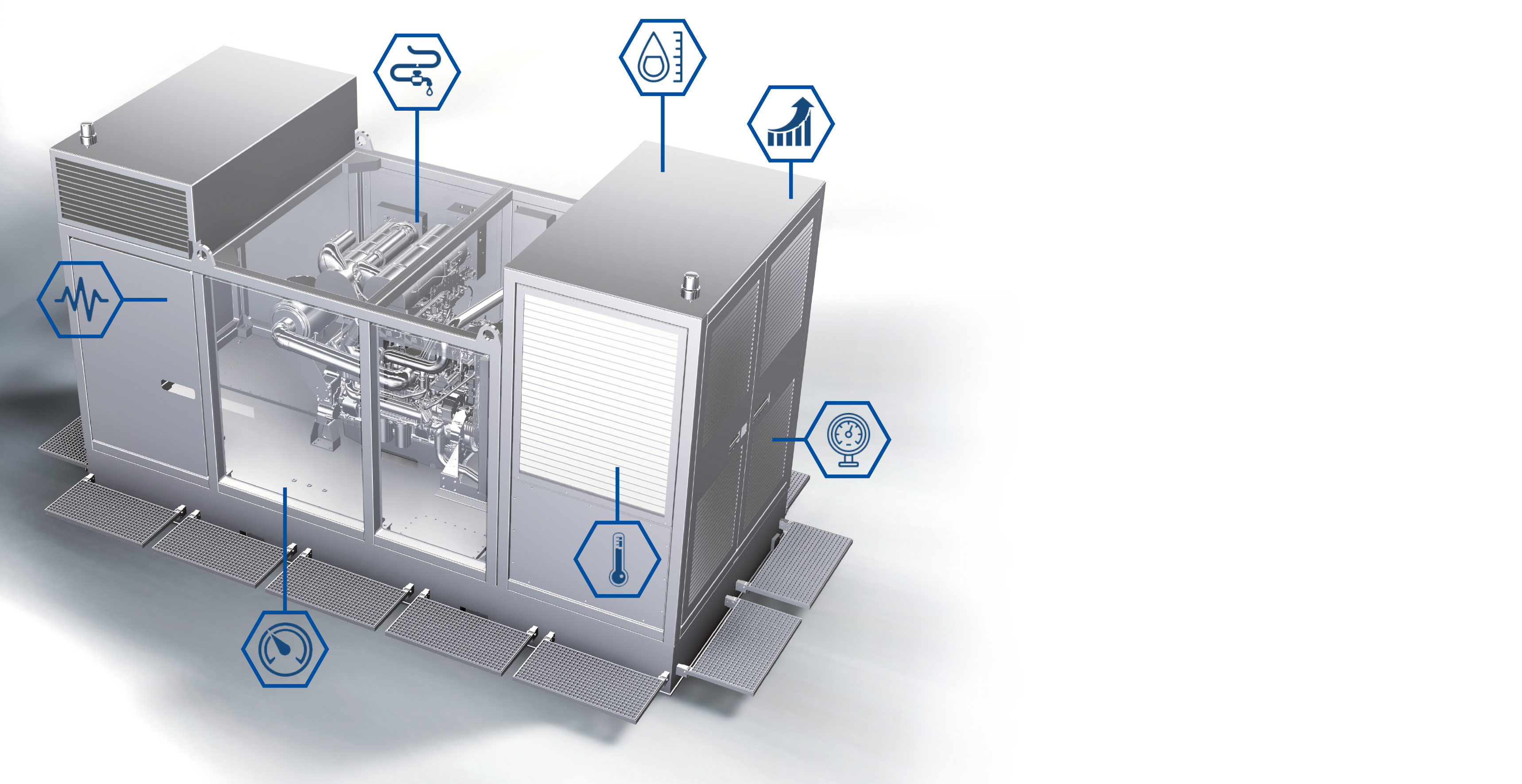

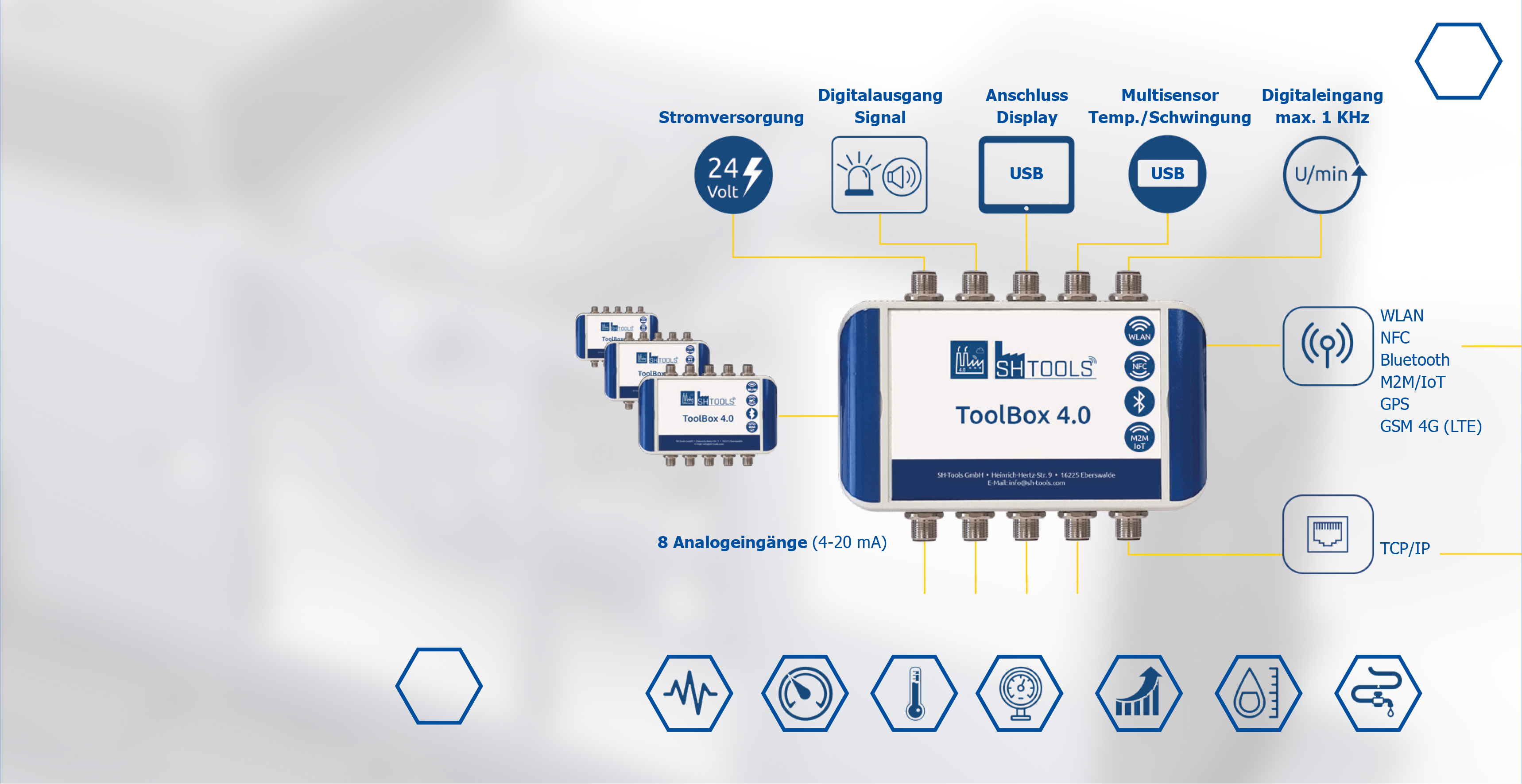

Our SmartTechnology works likewise: It is user-friendly and conserves companies' resources. Numerous sensors transmit crucial machinery data to the ToolBox, which forwards the data-evaluation to the operator's mobile, informing e.g. about an increase of the operating temperature - before the machinery in question is shut down for safety reasons of before a severe malfunction occures. Components and fluids can be replaced without unscheduled and cost-intensive machinery standstills as the ToolBox is able to keep track of the actual operating hours. All sensitive datas are of course highly protected.

Our ToolBox is able to do much more!

The interface of the ToolBox is highly intuitive. The SmartTechnology can be installed without requiring external programmers and special trainings for our clients' employees. Furthermore the installation of the ToolBox takes place without significant interruption of the production processes.

Our SmartTechnology allows the interlligent connection of industrial machinery as well as the comprehensive monitoring and controlling - and meets highest data security requirements all the time. The ToolBox is an independent network and does not intervene with control systems or with production processes.

Are you interested in avoiding production downtime by optimizing and digitizing the maintenance processes of your industrial machinery? Feel free to try our basis module during a two-month-free-trial. Please contact Mr. Kellermann if you wish for further information or operational support.

The ToolBox constantly measures and evaluates all relevant machine data like

Our ToolBox is also able to evaluate machine-specific data provided by for example hour meters.